Comparative characterization of vegetable oils from bulk suppliers/vendors in Nasarawa town market in Nigeria

DOI:

https://doi.org/10.26832/24566632.2022.070304Keywords:

Analysis, Characterization, Oil, Parameters, VegetableAbstract

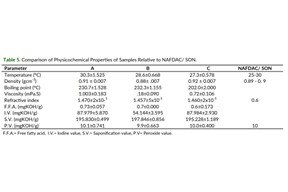

The comparative characterization of vegetable oils from bulk suppliers/vendors was made in Nasarawa town market in Nigeria. For this a total volume of 400 cm3 vegetable oils were collected (200 cm3 from the top and 200 cm3 from the bottom of storage after stirring) separately into labeled plastic bottles from three major suppliers. Composite of each sample were made and physicochemical properties including densities, temperatures, boiling points, viscosities, refractive indexes free fatty acid, iodine values, saponification values and peroxide values were determined using standard procedures. The results showed the density of sample ranging from 0.91 ± 0.007 to 0.92 ± 0.007 gcm-3; temperature of sample: 27.3 ± 0.578 to 30.3 ± 1.525 ºC; boiling point of sample 230.7 ± 1.528 ºC to 202 ± 2.000 ºC; viscosity of sample A: 1.03 ± 0.183 to 0.72 ± 0.106 mPa.S; refractive index of sample: 1.47012 ± 0.00002 to 1.45709 ± 0.00005; free fatty acid of sample A: 0.73 ± 0.057 mgKOH/g to 0.6 ± 0.173 mgKOH/g; iodine value of sample: 87.979 ± 5.870 mgKOH/g to 54.144 ± 3.595 mgKOH/g; saponification value of sample: 195.830 ± 0.499 mgKOH/g to 197.846 ± 0.856 mgKOH/g, and peroxide value of sample A: 10.1 ± 0.741 mgKOH/g to 9.9 ± 0.663 mgKOH/g. These parameters were also compared with the standards prescribed by NAFDAC and SON, which suggest that the sampled oil is suitable for consumer use. Thus, processing of vegetable oils from industrial and locally/traditionally extracted vegetable oils and vegetable oils supplied by the three vendors in the Nasarawa town market are hereby recommended as long as the suppliers maintain the standards of production, packaging and handling.

Downloads

References

Abbas, K., & Ong, S. K. (2019). Investigation of crude palm oil as an alternative processing oil in natural rubber: Effect of the unsaturated fatty acid. IOP Conference Series: Materials Science and Engineering 548, 012009, https://doi.org/10.1088/1757-899X/548/1/012009

Abdul-Hammed, M., Jaji, A. O., & Adegboyega, S. A. (2020). Comparative studies of thermophysical and physicochemical properties of shea butter prepared from cold press and solvent extraction methods. Journal of King Saud University, 32 (2020), 2343–2348.

Amin, M. Z., Islam, T., Mostof, F., Jashim Uddin M. J, Rahman M. M., & Satter M. A. (2019). Comparative assessment of the physicochemical and biochemical properties of native and hybrid varieties of pumpkin seed and seed oil (Cucurbita maxima Linn). Heliyon 5 (2019) e02994

AOAC, (2000). Official Methods of Analysis, seventeenth ed. Association of Official Analytical Chemists, William Hurwitz.

AOAC, (2003). Official Methods of Analysis, seventeenth ed. Association of Official Analytical Chemists.

AOAC, (2010). Association of Official Analytical Chemists. Official Methods of Analysis, 18th ed. Washington D.C., USA

Brahmi, F., Haddad., S. & Bouamara, K. (2020). Comparison of chemical composition and biological activities of Algerian seed oils of Pistacia lentiscus L., Opuntia ficus indica (L.) mill. and Argania spinosa L. skeels. Industrial Crops and Products. 151, 112456.

Claudia G., Paul, M., & Richard, C. (2021). Fraud in Fats and Oils. pp. 151-175. Elsevier Inc. https://doi.org/10.1016/B978-0-12-817242-1.00013-0

Gupta, M. K. (2017). Practical guide to vegetable oil processing (Second ed.). Amsterdam. ISBN 978-1-63067-051-1. OCLC 974497799

Hayichelaeh, C., Reuvekamp, L. A. E. M., Dierkes, W. K., Blume A., Noordermeer, J. W. M., & Sahakaro, K. (2020). Silica-reinforced natural rubber tire tread compounds containing bio- based process oils: II. Influence of epoxide and amino functional groups. Rubber Chem. Technol. 93, 195–207, https://doi.org/10.5254/rct.19.81461

Jan, A. (2018). The Nutrients in Fats and Oils: healthy-eating-diet-fat. pp.1-3. https://healthyeating.sfgate.com/nutrients-fats-oils-6398.html

Keogh-Brown, M.R., Jensen, H.T., Basu, S., et al. (2018). Evidence on the magnitude of the economic, health and population effects of palm cooking oil consumption: an integrated modelling approach with Thailand as a case study. Population Health Metrics. 17, 12 (2019), https://doi.org/10.1186/s12963-019-0191-y

Kumar, A., Sharma, A., & Upadhyaya, K. C. (2016). Vegetable Oil: Nutritional and Industrial Perspective. Current Genomics. 17(3), 230-40, https://doi.org/10.2174/1389202917666160202220107

Lamas, D. L., Constenla, D. T., & Raab, D. (2016). Effect of degumming process on physicochemical properties of sunflower oil. Biocatalysis and Agricultural Biotechnology, 6, 138–143.

Mark, G. & Pat N. (2018). Lipids, Oils, Fats, and Extracts. Food Science and the Culinary Arts. pp. 323-340, https://doi.org/10.1016/B978-0-12811816-0.00016-6

Mengistie T, Agegnehu Alemu and Alemayehu Mekonnen (2019). Comparison of physicochemical properties of edible vegetable oils commercially available in Bahir Dar, Ethiopia. Chemistry International, 4(2), 130-135.

Moresco, S., Giovanela M., Carli L. N., & Crespo, J. S. (2016). Development of passenger tire treads: Reduction in zinc content and utilization of a bio-based lubricant. Journal of Cleaner Production, 117, 199–206, https://doi.org/10.1016/j.jclepro.2016.01.013

NAFDAC. (2019). National Agency for Food and Drugs Administration and Control: Fats and Oils Regulations.

Norzahir S., Muhammad, F. H., & Syahrullail, S. (2019). The Use of Palm Oil as New Alternative Biolubricant for Improving Anti-Friction and Anti-Wear Properties.19(4),1126-1135, https://doi.org/10.1016/j.matpr.2019.11.005

Okparanta, S., Daminabo, V., & Solomon L. (2018). Assessment of rancidity and other physicochemical properties of edible oils (mustard and corn oils) stored at room temperature. Journal of Food and Nutrition Sciences, 6(3), 70–75.

Owuna, F. J. (2020). Stability of vegetable based oils used in the formulation of ecofriendly lubricants – a review. Egyptian Journal of Petroleum. 29(3), 251-256. https://doi.org/10.1016/j.ejpe.2020.09.003Get rights and content

Pechurai, W., Chiangta W., & Tharuen, P. (2015). Effect of vegetable oils as processing aids in SBR compounds. Macromolecular Symposia, 354, 191–196,https://doi.org/10.1002/masy.201400079

Philip D. B. (2022). Lipids in Plants and Algae: Fundamental Science to Industrial Applications in Advances in Botanical Research. 101, 2–468, https://www.sciencedirect.com/topics/food-science/vegetable-oil

Pike, O. A,. & O’Keefe, S. (2017). Fat Characterization. In: Nielsen, S.S. (eds) Food Analysis. Food Science Text Series. Springer, Cham. https://doi.org/10.1007/978-3-319-45776-5_23

Purcaro, G., Barp, L., Beccaria, M., & Conte, L.S. (2016). Characterisation of minor components in vegetable oil by comprehensive gas chromatography with dual detection. Food Chemistry, 212, 730–738, https://doi.org/10.1016/j.foodchem.2016.06.048

Roy K., Debnath, S. C. & Potiyaraj, P. (2020). A critical review on the utilization of various reinforcement modifiers in filled rubber composites. J. Elastomers Plast. 52, 167–193, https://doi.org/10.1177/0095244319835869

Said, G. (2022). Refining Vegetable Oils: Chemical and Physical Refining", The Scientific World Journal. 2022, 1-10, https://doi.org/10.1155/2022/6627013

S.O.N Standard Organization of Nigeria (2000) Standard for Edible Refined Palm Oil and Its Processed Form. 2-5.

Syed A. (2015). Specialty Oils and Fats in Food and Nutrition: Properties, Processing and Applications. A volume in Woodhead Publishing Series in Food Science, Technology and Nutrition. ISBN: 978-1-78242-376-8. pp. 349-357, https://doi.org/10.1016/C2014-0- 01770-4

Talbot, G. (2016). The stability and shelf life of fats and oils. In The stability and shelf life of food (pp. 461-503). Woodhead Publishing.

William, O., & Vida, O. E. (2015). Evaluation of Saponification value, Iodine value and Insoluble impurities in Coconut Oils from Jomoro District in the Western Region of Ghana. Asian Journal of Agriculture and Food Sciences, 3(5), 2321-1571.

Ying Q., Rudzińska M., Grygier A. & Przybylski R., (2020). Determination of triacylglycerols by HTGC-FID as a sensitive tool for the identification of rapeseed and olive oil adulteration. Molecules, 25(17), 3881.

Zhang, C., Garrison, T. F., Madbouly S. A., & Kessler, M. R. (2017). Recent advances in vegetable oil-based polymers and their composites. Progress in Polymer Science 71, 91–143, https://doi.org/10.1016/j.progpolymsci.2016.12.009

Zhou, Y., Zhao W., Lai Y., Zhang, B., & Zhang, D. (2020). Edible Plant Oil: Global Status, Health Issues, and Perspectives. Frontiers in Plant Science, 11, 1315,https://doi.org/10.3389/fpls.2020.01315

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Agriculture and Environmental Science Academy

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.