Purification of biodiesel-derived crude glycerol and its application in plasticizing cassava starch bioplastics

DOI:

https://doi.org/10.26832/24566632.2024.0903012Keywords:

Bioplastic, Cassava starch, Glycerol, PurificationAbstract

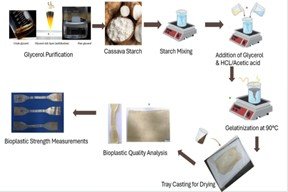

This study focused on purifying crude glycerol, a by-product of biodiesel production, using acid-precipitation, methanol extraction, and adsorption with acid-activated charcoal. Among the acids tested—sulfuric, phosphoric, and hydrochloric—phosphoric acid proved most effective, producing the clearest glycerol with minimal salt deposition. The purified glycerol was then used to produce bioplastics, which were tested for mechanical properties. The results indicated that Phosphoric acid yielded the clearest glycerol with minimal salt deposition. The resultant salt, potassium phosphate (K2PO4), has potential as a fertilizer. The purified glycerol showed increased density and viscosity, indicating higher purity compared to crude glycerol. The density of the purified glycerol was closer to that of analytical-grade glycerol. Bioplastic 1 (using analytical-grade glycerol) exhibited the highest tensile strength, withstanding up to 4.3N and extending about 104mm before breaking. Bioplastic 2 (using glycerol purified with hydrochloric acid) withstood up to 4.1N, while Bioplastic 3 (using glycerol purified with acetic acid) endured the least stress, withstanding up to 3.8N and extending up to 87mm before breaking. The study demonstrates that phosphoric acid is an effective agent for purifying crude glycerol, significantly enhancing its quality. The purified glycerol, in turn, improves the mechanical properties of bioplastics, making them more durable and suitable for a range of applications. This process not only adds value to the biodiesel production by-product but also contributes to the development of stronger, more versatile bioplastics.

Downloads

References

Abang, S., Wong, F., Sarbatly, R., Sariau, J., Baini, R., & Besar, N. A. (2023). Bioplastic classifications and innovations in antibacterial, antifungal, and antioxidant applications. In Journal of Bioresources and Bioproducts. https://doi.org/10.1016/j.jobab.2023.06.005

Abbott, A. P., Abolibda, T. Z., Davis, S. J., Emmerling, F., Lourdin, D., Leroy, E., & Wise, W. R. (2014). Glycol based plasticisers for salt modified starch. RSC Advances. https://doi.org/10.1039/c4ra06220e

Abbott, A. P., Abolibda, T. Z., Qu, W., Wise, W. R., & Wright, L. A. (2017). Thermoplastic starch-polyethylene blends homogenised using deep eutectic solvents. RSC Advances. https://doi.org/10.1039/c7ra00135e

Abstracts of the 17th International Symposium on Bioluminescence and Chemiluminescence (ISBC 2012). (2012). Luminescence. https://doi.org/10.1002/bio.2341

Ahimbisibwe, M., Banadda, N., Seay, J., Nabuuma, B., Atwijukire, E., Wembabazi, E., & Nuwamanya, E. (2019a). Influence of Weather and Purity of Plasticizer on Degradation of Cassava Starch Bioplastics in Natural Environmental Conditions. Journal of Agricultural Chemistry and Environment. https://doi.org/10.4236/jacen.2019.84018

Ahimbisibwe, M., Banadda, N., Seay, J., Nabuuma, B., Atwijukire, E., Wembabazi, E., & Nuwamanya, E. (2019b). Influence of Weather and Purity of Plasticizer on Degradation of Cassava Starch Bioplastics in Natural Environmental Conditions. Journal of Agricultural Chemistry and Environment. https://doi.org/10.4236/jacen.2019.8418

Amin, M. R., Chowdhury, M. A., & Kowser, M. A. (2019). Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch. Heliyon. https://doi.org/10.1016/j.heliyon.2019.e02009

Anđelović, S., Božinović, M., Ćurić, Ž., Šalić, A., Jurinjak Tušek, A., Kučan, K. Z., Rogošić, M., Radović, M., Cvjetko Bubalo, M., & Zelić, B. (2022). Deep Eutectic Solvents for Biodiesel Purification in a Microextractor: Solvent Preparation, Selection and Process Optimization. Bioengineering. https://doi.org/10.3390/bioengineering9110665

Ardi, M. S., Aroua, M. K., & Hashim, N. A. (2015). Progress, prospect and challenges in glycerol purification process: A review. In Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2014.10.091

Armylisas, A. H. N., Hoong, S. S., & Tuan Ismail, T. N. M. (2023). Characterization of crude glycerol and glycerol pitch from palm-based residual biomass. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-023-04003-4

Astm. (2012). ASTM Standards: G31-72. In Annual Book of ASTM Standards (Vol. 72). https://doi.org/10.1520/G0031-72R04

Ayala, M., Thomsen, M., & Pizzol, M. (2023). Life Cycle Assessment of pilot scale production of seaweed-based bioplastic. Algal Research. https://doi.org/10.1016/j.algal.2023.103036

Basiak, E., Lenart, A., & Debeaufort, F. (2018). How glycerol and water contents affect the structural and functional properties of starch-based edible films. Polymers. https://doi.org/10.3390/polym10040412

Basiak, E., Linke, M., Debeaufort, F., Lenart, A., & Geyer, M. (2022). Impact of Biodegradable Materials on the Quality of Plums. Coatings. https://doi.org/10.3390/coatings12020226

Ben, Z. Y., Samsudin, H., & Yhaya, M. F. (2022). Glycerol: Its properties, polymer synthesis, and applications in starch based films. In European Polymer Journal. https://doi.org/10.1016/j.eurpolymj.2022.111377

Buddhakala, M., & Buddhakala, N. (2023). Physical, Mechanical and Antibacterial Properties of Biodegradable Bioplastics from Polylactic Acid and Corncob Fibers with Added Nano Titanium Dioxide. Trends in Sciences. https://doi.org/10.48048/tis.2023.6473

Cai, T., Li, H., Zhao, H., & Liao, K. (2013). Purification of crude glycerol from waste cooking oil based biodiesel production by orthogonal test method. China Petroleum Processing and Petrochemical Technology.

Censi, V., Saiano, F., Bongiorno, D., Indelicato, S., Napoli, A., & Piazzese, D. (2022). Bioplastics: A new analytical challenge. In Frontiers in Chemistry. https://doi.org/10.3389/fchem.2022.971792

Chen, C. Y., Lee, M. H., Leong, Y. K., Chang, J. S., & Lee, D. J. (2020). Biodiesel production from heterotrophic oleaginous microalga Thraustochytrium sp. BM2 with enhanced lipid accumulation using crude glycerol as alternative carbon source. Bioresource Technology. https://doi.org/10.1016/j.biortech.2020.123113

Chen, J., Yan, S., Zhang, X., Tyagi, R. D., Surampalli, R. Y., & Valéro, J. R. (2018). Chemical and biological conversion of crude glycerol derived from waste cooking oil to biodiesel. Waste Management. https://doi.org/10.1016/j.wasman.2017.10.044

Christy, S., Noschese, A., Lomelí-Rodriguez, M., Greeves, N., & Lopez-Sanchez, J. A. (2018). Recent progress in the synthesis and applications of glycerol carbonate. In Current Opinion in Green and Sustainable Chemistry. https://doi.org/10.1016/j.cogsc.2018.09.003

Cinar, S. O., Chong, Z. K., Kucuker, M. A., Wieczorek, N., Cengiz, U., & Kuchta, K. (2020). Bioplastic production from microalgae: A review. In International Journal of Environmental Research and Public Health. https://doi.org/10.3390/ijerph17113842

Coffinet, S., Huguet, A., Williamson, D., Bergonzini, L., Anquetil, C., Majule, A., & Derenne, S. (2015). Occurrence and distribution of glycerol dialkanol diethers and glycerol dialkyl glycerol tetraethers in a peat core from SW Tanzania. Organic Geochemistry. https://doi.org/10.1016/j.orggeochem.2015.03.013

Coppola, G., Gaudio, M. T., Lopresto, C. G., Calabro, V., Curcio, S., & Chakraborty, S. (2021). Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. In Earth Systems and Environment. https://doi.org/10.1007/s41748-021-00208-7

Cucina, M., Carlet, L., De Nisi, P., Somensi, C. A., Giordano, A., & Adani, F. (2022). Degradation of biodegradable bioplastics under thermophilic anaerobic digestion: A full-scale approach. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2022.133232

Dibha, A. F., Masruri, M., & Srihardyastutie, A. (2023). Degradable Bioplastic Developed from Pine-Wood Nanocellulose as a Filler Combined with Orange Peel Extract. Indonesian Journal of Chemistry. https://doi.org/10.22146/ijc.75520

Ephraim, N., Patrick, R. R., Ssetumba, M., Samuel, K., Joseph, H., & Yona, B. (2014). Influence of spectral properties on cassava leaf development and metabolism. African Journal of Biotechnology. https://doi.org/10.5897/ajb2013.12795

Epure, V., Griffon, M., Pollet, E., & Avérous, L. (2011). Structure and properties of glycerol-plasticized chitosan obtained by mechanical kneading. Carbohydrate Polymers. https://doi.org/10.1016/j.carbpol.2010.09.003

Fauziyah, S. N., Mubarak, A. S., & Pujiastuti, D. Y. (2021). Application of glycerol on bioplastic based carrageenan waste cellulose on biodegradability and

mechanical properties bioplastic. IOP Conference Series: Earth and Environmental Science. https://doi.org/10.1088/1755-1315/679/1/012005

FEWSNET. (2023). FEWS | Early Warning and Environmental Monitoring Program. USGS FEWS NET Project.

Gabriel, A. A., Solikhah, A. F., & Rahmawati, A. Y. (2021). Tensile Strength and Elongation Testing for Starch-Based Bioplastics using Melt Intercalation Method: A Review. Journal of Physics: Conference Series. https://doi.org/10.1088/1742-6596/1858/1/012028

Gama, N. V., Silva, R., Costa, M., Barros-Timmons, A., & Ferreira, A. (2016). Statistical evaluation of the effect of formulation on the properties of crude glycerol polyurethane foams. Polymer Testing. https://doi.org/10.1016/j.polymertesting.2016.10.006

Gama, N. V., Silva, R., Mohseni, F., Davarpanah, A., Amaral, V. S., Ferreira, A., & Barros-Timmons, A. (2018). Enhancement of physical and reaction to fire properties of crude glycerol polyurethane foams filled with expanded graphite. Polymer Testing. https://doi.org/10.1016/j.polymertesting.2018.05.012

García, J. I., García-Marín, H., & Pires, E. (2014). Glycerol based solvents: Synthesis, properties and applications. In Green Chemistry. https://doi.org/10.1039/c3gc41857j

Gironi, F., & Piemonte, V. (2011). Life cycle assessment of polylactic acid and polyethylene terephthalate bottles for drinking water. Environmental Progress and Sustainable Energy. https://doi.org/10.1002/ep.10490

Glycerol: Properties and production. (2010). RSC Green Chemistry. https://doi.org/10.1039/9781849731089-00001

Hájek, M., & Skopal, F. (2010). Treatment of glycerol phase formed by biodiesel production. Bioresource Technology. https://doi.org/10.1016/j.biortech.2009.12.094

Hambali, E., Fitria, R., & Sari, V. I. (2022). Glycerol and Derivatives. In Biorefinery of Oil Producing Plants for Value-Added Products: Volume 1.

https://doi.org/10.1002/9783527830756.ch24

Harabi, M., Bouguerra, S. N., Marrakchi, F., Chrysikou, L. P., Bezergianni, S., & Bouaziz, M. (2019). Biodiesel and crude glycerol fromwaste frying oil: Production, characterization and evaluation of biodiesel oxidative stability with diesel blends. Sustainability (Switzerland). https://doi.org/10.3390/su11071937

Harnkarnsujarit, N., Wongphan, P., Chatkitanan, T., Laorenza, Y., & Srisa, A. (2021). Bioplastic for Sustainable Food Packaging. In Sustainable Food Processing and Engineering Challenges. https://doi.org/10.1016/B978-0-12-822714-5.00007-3

Kapanen, A. (2012). Ecotoxicity assessment of biodegradable plastics and sewage sludge in compost and in soil. In VTT Science.

Kim, T., & Boehman, A. L. (2021). Life-Cycle Greenhouse Gas Emissions Assessment of Novel Dimethyl Ether-Glycerol Blends for Compression-Ignition Engine Application. ACS Sustainable Chemistry and Engineering. https://doi.org/10.1021/acssuschemeng.1c03783

Kongjao, S., Damronglerd, S., & Hunsom, M. (2010). Purification of crude glycerol derived from waste used-oil methyl ester plant. Korean Journal of Chemical Engineering. https://doi.org/10.1007/s11814-010-0148-0

Kongjao, S., Damronglerd, S., & Hunsom, M. (2011). Electrochemical reforming of an acidic aqueous glycerol solution on Pt electrodes. Journal of Applied

Electrochemistry. https://doi.org/10.1007/s10800-010-0226-3

Kumar, L. R., Yellapu, S. K., Tyagi, R. D., & Zhang, X. (2019). A review on variation in crude glycerol composition, bio-valorization of crude and purified glycerol as carbon source for lipid production. In Bioresource Technology. https://doi.org/10.1016/j.biortech.2019.122155

Kumar, L. R., Yellapu, S. K., Yan, S., Tyagi, R. D., & Drogui, P. (2021). Elucidating the effect of impurities present in different crude glycerol sources on lipid and citric acid production by Yarrowia lipolytica SKY7. Journal of Chemical Technology and Biotechnology. https://doi.org/10.1002/jctb.6531

Liu, Y., Zhong, B., & Lawal, A. (2022). Recovery and utilization of crude glycerol, a biodiesel byproduct. In RSC Advances. https://doi.org/10.1039/d2ra05090k

Luo, Z., Miao, J., Luo, W., Li, G., Du, Y., & Yu, X. (2018). Crude glycerol from biodiesel as a carbon source for production of a recombinant highly thermostable β-mannanase by Pichia pastoris. Biotechnology Letters. https://doi.org/10.1007/s10529-017-2451-x

Mcquade, J. F., & Creighton, T. E. (1970). Purification and Comparison of the N‐(5′‐Phosphoribosyl)anthranilic Acid Isomerase/Indole‐3‐glycerol Phosphate Synthetase of Tryptophan Biosynthesis from Three Species of Enterobacteriaceae. European Journal of Biochemistry. https://doi.org/10.1111/j.1432-1033.1970.tb01072.x

Mitrea, L., Călinoiu, L. F., Teleky, B. E., Szabo, K., Martău, A. G., Ştefănescu, B. E., Dulf, F. V., & Vodnar, D. C. (2022). Waste cooking oil and crude glycerol as efficient renewable biomass for the production of platform organic chemicals through oleophilic yeast strain of Yarrowia lipolytica. Environmental Technology and Innovation. https://doi.org/10.1016/j.eti.2022.102943

Nanda, M; Yuan, Z., Qin, W., & M.A, Poirier; Xu, C. (2015). Purification of crude glycerol using acidification: effects of acid types and product characterization. Austin Journal of Chemical Engineering.

Nanda, M. R., Zhang, Y., Yuan, Z., Qin, W., Ghaziaskar, H. S., & Xu, C. (2016). Catalytic conversion of glycerol for sustainable production of solketal as a fuel additive: A review. In Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2015.12.008

Nanda, M., Yuan, Z., & Qin, W. (2014). Purification of crude glycerol using acidification: effects of acid types and product characterization. 1(1), 1–7.

Nesrine, L., Salima, K., Lamine, K. M., Belaid, L., Souad, Bk., Lamine, G. M., Sihem, A., & Imène, F. (2020). Phylogenetic characterization and screening of halophilic bacteria from Algerian salt lake for the production of biosurfactant and enzymes. World Journal of Biology and Biotechnology. https://doi.org/10.33865/wjb.005.02.0294

Nuwamanya, E., Baguma, Y., Emmambux, N., & Rubaihayo, P. (2010). Crystalline and pasting properties of cassava starch are influenced by its molecular properties. African Journal of Food Science.

Ooi, Z. X., Ismail, H., Bakar, A. A., & Aziz, N. A. A. (2012). The Comparison Effect of Sorbitol and Glycerol as Plasticizing Agents on the Properties of Biodegradable Polyvinyl Alcohol/Rambutan Skin Waste Flour Blends. Polymer - Plastics Technology and Engineering. https://doi.org/10.1080/03602559.2011.639827

Pal, P., & Chaurasia, S. P. (2016). Characterization of Crude and Purified Glycerol from Biodiesel Production and Purification Techniques. Vth International Symposium on “Fusion of Science & Technology.

Pal, P., Chaurasia, S. P., Upadhyaya, S., Agarwal, M., & Sridhar, S. (2018). Glycerol Purification Using Membrane Technology. In Membrane Processes.

https://doi.org/10.1002/9781119418399.ch15

Razza, F., Innocenti, F. D., Dobon, A., Aliaga, C., Sanchez, C., & Hortal, M. (2015). Environmental profile of a bio-based and biodegradable foamed packaging prototype in comparison with the current benchmark. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2015.04.033

Rosenboom, J. G., Langer, R., & Traverso, G. (2022). Bioplastics for a circular economy. In Nature Reviews Materials. https://doi.org/10.1038/s41578-021-00407-8

Rywińska, A., Juszczyk, P., Wojtatowicz, M., Robak, M., Lazar, Z., Tomaszewska, L., & Rymowicz, W. (2013). Glycerol as a promising substrate for Yarrowia lipolytica biotechnological applications. In Biomass and Bioenergy. https://doi.org/10.1016/j.biombioe.2012.11.021

Siddiqui, S. A., Yang, X., Deshmukh, R. K., Gaikwad, K. K., Bahmid, N. A., & Castro-Muñoz, R. (2024). Recent advances in reinforced bioplastics for food packaging – A critical review. In International Journal of Biological Macromolecules. https://doi.org/10.1016/j.ijbiomac.2024.130399

Sinaga, M. S., Ramadhan, M. R., Rico, G., & Sitompul, W. G. T. (2019). Effect of Acidification Mole Ratio and Solvent Volume Ratio of Glycerol Purification. IOP Conference Series: Materials Science and Engineering. https://doi.org/10.1088/1757-899X/505/1/012116

Suriaini, N., Arpi, N., Syamsuddin, Y., & Supardan, M. D. (2021). Use of Crude Glycerol for Glycerolysis of Free Fatty Acids in Crude Palm Oil. International Journal of Technology. https://doi.org/10.14716/ijtech.v12i4.4165

Takamura, K., Fischer, H., & Morrow, N. R. (2012). Physical properties of aqueous glycerol solutions. Journal of Petroleum Science and Engineering.

https://doi.org/10.1016/j.petrol.2012.09.003

Tan, H. W., Abdul Aziz, A. R., & Aroua, M. K. (2013). Glycerol production and its applications as a raw material: A review. In Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2013.06.035

Tan, K. O., Mardini, M., Yang, C., Ardenkjær-Larsen, J. H., & Griffin, R. G. (2019). Three-spin solid effect and the spin diffusion barrier in amorphous solids. Science Advances. https://doi.org/10.1126/sciadv.aax2743

Thompson, J. C., & He, B. B. (2006). Characterization of crude glycerol from biodiesel production from multiple feedstocks. Applied Engineering in Agriculture, 22(2), 261–265. https://doi.org/10.13031/2013.20272

Through, M. S., Capillary, E., Fitting, H. P., Tissue, K., & C-line, N. H. (2009). Determination of Free and Total Glycerin in B100 Biodiesel. Reporter, 36(May).

Vassilev, N., Malusa, E., Requena, A. R., Martos, V., López, A., Maksimovic, I., & Vassileva, M. (2017). Potential application of glycerol in the production of plant beneficial microorganisms. Journal of Industrial Microbiology and Biotechnology. https://doi.org/10.1007/s10295-016-1810-2

Wan Isahak, W. N. R., Che Ramli, Z. A., Ismail, M., Jahim, J. M., & Yarmo, M. A. (2015a). Recovery and purification of crude glycerol from vegetable oil transesterification. Separation and Purification Reviews, 44(3), 250–267. https://doi.org/10.1080/15422119.2013.851696

Wan Isahak, W. N. R., Che Ramli, Z. A., Ismail, M., Jahim, J. M., & Yarmo, M. A. (2015b). Recovery and purification of crude glycerol from vegetable oil transesterification. Separation and Purification Reviews. https://doi.org/10.1080/15422119.2013.851696

Yang, Y. M., Kim, K. J., & Lee, Y. (2008). Glycerol separation from biodiesel byproduct. Journal of the Korean Industrial and Engineering Chemistry.

Yuliana, M., Trisna, L., Sari, F., & Lunardi, V. B. (2021). Glycerol purification using reactivated spent bleaching earth from palm oil refineries: Zero-waste approach. Journal of Environmental Chemical Engineering. https://doi.org/10.1016/j.jece.2021.105239

Yung, C. L., Subramaniam, V., & Yusoff, S. (2021). Life cycle assessment for the production of palm biodiesel. Journal of Oil Palm Research. https://doi.org/10.21894/jopr.2020.0080

Zhang, M., & Wu, H. (2015). Effect of major impurities in crude glycerol on solubility and properties of glycerol/methanol/bio-oil blends. Fuel. https://doi.org/10.1016/j.fuel.2015.06.062

Zhao, X., Wang, Y., Chen, X., Yu, X., Li, W., Zhang, S., Meng, X., Zhao, Z. M., Dong, T., Anderson, A., Aiyedun, A., Li, Y., Webb, E., Wu, Z., Kunc, V., Ragauskas, A., Ozcan, S., & Zhao, H. (2023). Sustainable bioplastics derived from renewable natural resources for food packaging. In Matter. https://doi.org/10.1016/j.matt.2022.11.006

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Agriculture and Environmental Science Academy

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.